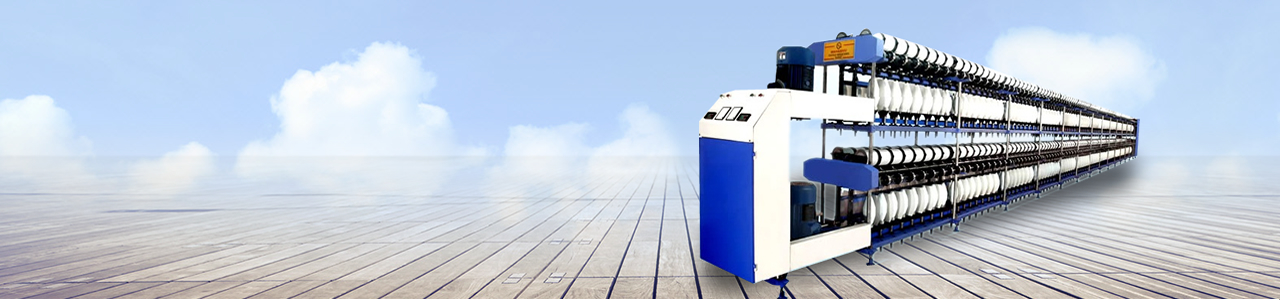

INFRASTRUCTURE

The company's operations are highly efficient and effective due to the sophisticated infrastructure of state-of-art production equipment and efficient human resources. Our production equipment is well maintained to produce the best quality textile machinery. We are known for our top-grade Two For One Twister, Cop Winder, Hollow Twister,and more

Innovation is the key to our success. Years of experience in the industry have led us to constantly upgrade our processes & technologies to match the global standards and meet the changing needs of our customers. We give meticulous attention to research and development activities to keep abreast of changing technologies in the textile sector.

The sophisticated infrastructure consists of a workshop spread over an area of 5000 sq. meters. The workshop includes all modern equipment such as CNC lathes, drilling machines, boring machines, shapers, and other mechanical equipment. We have invested in the latest machinery for our production facility. Frequently, we upgrade the older machinery to newer machinery to enable the company to operate more efficiently. The quality control department has a team of efficient quality analysts and research engineers. The company also has imported German-made machines for spindle balancing. We never compromise on the quality of our products. To ensure quality control, we enforce it right from the purchase of the raw materials to the final dispatch of finished goods.

Our professional team consists of an efficient administrative and technical staff, drawing inspiration from its management. We have a large workforce of skilled and unskilled personnel working in various capacities. Customer services are given the highest priority, and product development is provided the maximum thrust.

The basis of our machinery design is always performance. This means smooth organizing of production, as well as easy usability and capacity.